UF (Urea-Formaldehyde): Properties, Applications, and Sustainability

Urea-Formaldehyde (UF) is a thermosetting polymer that has been widely used in the plastics industry for many years. It is a type of resin that is formed by combining urea and formaldehyde. UF has excellent properties that make it suitable for a variety of applications, including in the manufacturing of consumer products, construction materials, and industrial products.

The history of UF dates back to the early 20th century when researchers discovered that urea and formaldehyde could be combined to create a synthetic resin. In the 1920s, UF was first used commercially in the production of moulded products. The development of UF was a significant breakthrough in the plastics industry as it provided a cheap and durable alternative to natural materials.

What is Urea-Formaldehyd?

UF is a thermosetting polymer that has excellent mechanical properties. It has high strength, good dimensional stability, and low water absorption. UF is also resistant to chemicals and heat, making it suitable for use in a wide range of applications.

UF has a low glass transition temperature, which softens at relatively low temperatures. This makes it easy to shape and mould into various forms. UF also has good adhesion properties, which makes it suitable for bonding different materials.

Industrial Usage of UF

UF is widely used in producing various industrial products, including laminates, particleboards, medium-density fiberboards, and adhesives. UF is also used as a binder in the manufacturing of abrasives, insulation materials, and filters.

UF is particularly suitable for use in the construction industry as it has good fire resistance and insulation properties. It is used in the production of ceiling tiles, wall panels, and door skins.

Application Areas of UF

UF has a wide range of application areas, including:

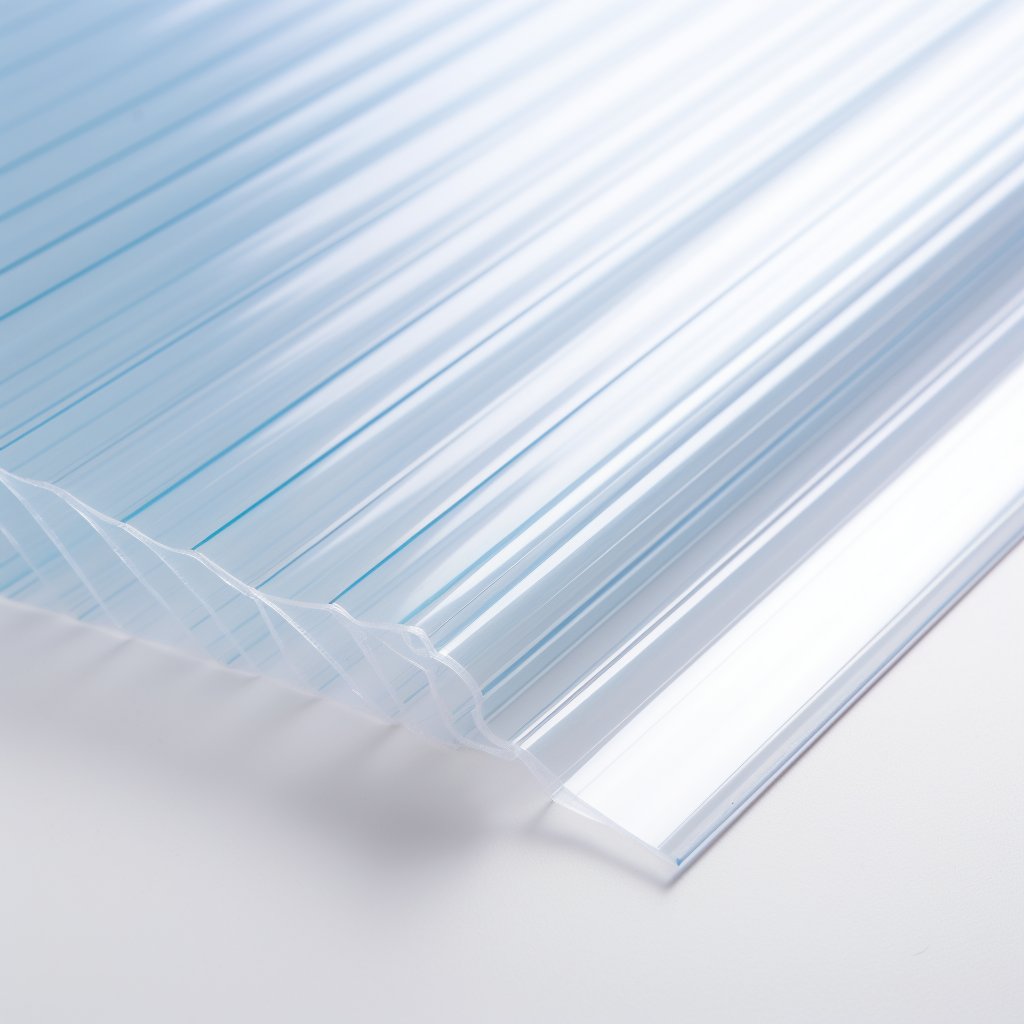

- Construction materials: UF is used in the production of construction materials such as particleboards, fiberboards, and laminates.

- Consumer products: UF is used in the production of a variety of consumer products, including kitchen utensils, buttons, and electrical switches.

- Insulation materials: UF is used in the production of insulation materials such as foam boards and pipe insulation.

- Industrial products: UF is used as a binder in the manufacturing of abrasives, filters, and insulation materials.

Consumer Product Examples of UF

UF is widely used in the production of consumer products. Some examples of consumer products that are made using UF include:

- Kitchen utensils – UF is used in the production of kitchen utensils such as bowls, plates, and cutlery.

- Buttons – UF is used in the production of buttons for clothing.

- Electrical switches – UF is used in the production of electrical switches and sockets.

- Toys – UF is used in the production of toys such as building blocks and puzzle pieces.

Recycling of UF (Urea-Formaldehyde)

UF is not widely recycled due to its difficulty separating it from other plastics. It is also not biodegradable, which means it remains in the environment for a long time.

Recycling UF can be challenging due to its chemical composition and the difficulty in separating it from other plastics. However, some recycling methods can be used to recover and reuse UF.

One method is mechanical recycling, where UF is ground into small particles and mixed with other materials to create composite materials. This method is limited in its effectiveness due to the difficulty in separating UF from other plastics.

Another method is chemical recycling, where UF is broken down into its constituent parts using chemicals or heat. This method is more effective in recovering UF, but it can be expensive and energy-intensive.

Advantages of UF Recycling

The main advantage of UF recycling is that it reduces waste and conserves resources. By recovering and reusing UF, less material is sent to landfills, and less energy is required to produce new plastics.

Another advantage is that recycled UF can be used in a variety of applications, including composite materials and building products, which reduces the need for virgin plastics.

Disadvantages of UF Recycling

The main disadvantage of UF recycling is that it can be expensive and difficult due to the chemical composition of UF. This can make it less economically viable compared to other plastics that are easier to recycle.

Another disadvantage is that recycled UF may not have the same properties as virgin UF, which can limit its use in certain applications.

Environmental and Global Impact

The recycling of UF can have a positive environmental impact by reducing waste and conserving resources. However, the energy required to recycle UF can also have a negative environmental impact, depending on the energy source.

In terms of the global impact, the recycling of UF can help to reduce the demand for virgin plastics, which can help to reduce greenhouse gas emissions and the consumption of fossil fuels. This can positively impact the environment and contribute to global efforts to reduce carbon emissions and combat climate change.

Advantages of UF Compared to Alternative Plastics

UF has several advantages over alternative plastics, including:

- Low cost – UF is a relatively inexpensive material compared to other plastics.

- Good mechanical properties – UF has excellent mechanical properties, including high strength and good dimensional stability.

- Resistance to heat and chemicals – UF is highly resistant to heat and chemicals, making it suitable for use in a variety of applications.

- Easy to shape – UF can be easily shaped and moulded into different forms.

Disadvantages of UF Compared to Alternative Plastics

UF also has some disadvantages compared to alternative plastics, including:

- Formaldehyde emissions – UF can release formaldehyde, a potential carcinogen, especially when exposed to high temperatures.

- Low thermal stability – UF has a low glass transition temperature, which limits its use in high-temperature applications.

- Low moisture resistance – UF has relatively low moisture resistance, which limits its use in applications where it may be exposed to water or humidity.

Overall, while UF recycling can be challenging, it offers a potential solution for reducing waste and conserving resources. However, more research and development is needed to make UF recycling more cost-effective and environmentally sustainable.

Market Price Developments

The price of UF can vary depending on supply and demand. UF is typically less expensive than other plastics, contributing to its wide use in the plastics industry.

Future Market Prognosis

The demand for UF is expected to increase in the coming years due to its wide range of applications and low cost. However, concerns over formaldehyde emissions may lead to increased regulation and a shift towards alternative plastics in some applications.

Overall, UF is likely to remain an essential material in the plastics industry, especially in applications where cost is a significant factor. However, developing alternative plastics with improved properties may lead to a shift away from UF in some applications. The key to the future market prognosis of UF will depend on its ability to meet the market’s evolving needs, including increased sustainability and reduced emissions.

Urea-Formaldehyde

In conclusion, urea-formaldehyde (UF) has been an important plastic in the manufacturing industry for many years due to its low cost and good mechanical properties. UF has been used in a variety of applications, including in consumer products, building materials, and automotive components. However, the concerns over formaldehyde emissions and the difficulty in recycling UF have led to increased scrutiny and the development of alternative plastics. While UF recycling offers a potential solution for reducing waste and conserving resources, more research and development is needed to make UF recycling more cost-effective and environmentally sustainable.

As the demand for sustainable plastics continues to grow, it is important for professionals in the plastics and recycling industries to stay informed about the latest developments and innovations in UF and alternative plastics.